The company

Desch Antriebstechnik designs and produces drive solutions and offers complete solutions for almost every industry. In addition, they develop pioneering technologies, such as the Tevox®. A system solution for the electric direct drive for shredders in recycling applications.

Task

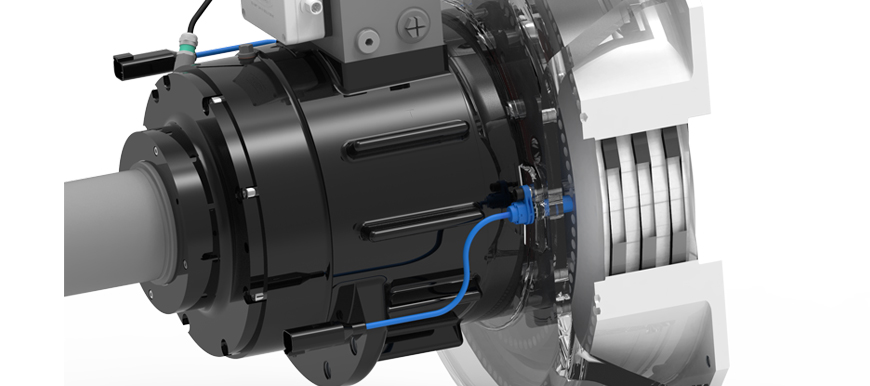

The product is a hydraulically actuated dry-running multi-plate clutch for mobile construction and work machines (product name: Planox PHRA 143/1 SR).

The clutch is mounted/flanged directly to the diesel engine of the machine. The role of the system is to accelerate the main tool of the machine.

This usually involves large rotating masses, in particular drums and flywheels (e.g. in stone crushers, wood chippers, cold milling machines). As soon as the control unit receives a start signal, a soft start is performed. The control unit moves the clutch and searches for the grinding point.

The mass moment of inertia is then accelerated with the slipping clutch until synchronization is achieved.

Solution

Throughout operation, the RHEINTACHO sensors monitor the input speed/engine speed (external sensor) and the output speed of the clutch (internal sensor). The sensors scan holes in the gear rim and the clutch hub. These signals are required to control the soft start and for slip and error monitoring. In particular, the high number of increments that can be achieved with the FQ sensors helps us with fine control and clean error detection. The environmental conditions in the construction machine are relatively harsh, with a lot of dust and dirt and high temperatures near the engine to contend with. Very good sealing is achieved thanks to the two connector variants with overmolding on the back. Perfect for use in critical environmental conditions, the FQ series achieves protection classes IP67/IP69K up to the plug connection. Thanks to different sensor lengths, cable outlet directions, and the variety of available connectors, the series offers the user a high degree of flexibility.