RHEINTACHO portable measuring units have become the product of choice for virtually all commissioning, maintenance and servicing work within plants. Boasting exceptional precision and a design tailored for industry, our products have a 117 year track record of

- Extending and optimally exploiting the service life of plants and machines

- Accelerated commissioning periods

- Improved operating reliability

- Increased system availability

- Optimised operating procedures

- Reduced downtime thanks to preventive maintenance

- Forward-planning of costs

The applications of the digital hand-tachometer rotaro Te include commissioning and maintenance of lifts within the plant.

Application report - Yarn speed measurement using the digital hand-tachometer rotaro T

Task: The yarn speed is to be measured on a plain stitch circular knitting machine. This type of machine is usually used to produce simple knitted products such as T-shirts and underwear. In this case, a typical single jersey T-shirt is being knitted.

Application report - Determining the optimum ignition timing using a portable stroboscope RT STROBE pocketLED with trigger

Task: Construction of a test stand for capturing ignition point and determine stability/repeatability. The tools for this task are: A stroboscope RT STROBE pocketLED A4-3200 with external trigger input and a conventional clamp meter.

Application report - Gearbox monitoring with analog display of mechanical hand-tachometers HTM

Task: For monitoring the reaction speed of centrifugal releases, speed measurement in steam locomotives and battery-powered locomotives. In particular, checking the permanently installed speed measuring devices and the emergency releases (brakes) is carried out with the mechanical hand-tachometer.

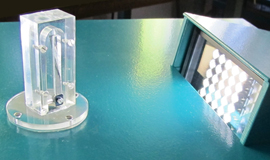

Application report - Demonstration model "Oscillating Reed" with stationary stroboscope RT STROBE qbLEDs

Task: For a local museum, the task was to develop a demonstration model for an oscillating accordion reed to expand its exhibition of lfM. The museum visitors should be shown optically, how to achieve sound inside accordions, harmoniums and harmonicas.

Application report - Quality control on wallpaper coating machines with stationary stroboscope RT STROBE 12000 LED

Task: During quality control on wallpaper coating machines for glass-textile wallpaper, it is necessary to control the straightness of the wefts at an average of once per hour.

Application report - Fan speed measurement and inspection Tachometer control with portable stroboscope RT STROBE pocketLED LASER

Task: When measuring the wheel rotational speed, it is important to calibrate the tachometer or prove that the determined maximum speed is reached. When measuring the ventilator rotational speed...

Application report - Metal extraction from waste incineration residues with portable stroboscope RT STROBE qbLED

Task: After burning household and commercial waste, there are several types of residue in the slag including ash, clay and glass shards as well as metals. Magnetic metals are relatively easy to regain. However, for non-ferrous metals such as aluminium, brass and copper as well as precious metals, this is much more difficult.

Application report - Quality control of measuring devices for clinical diagnostics with customized modification of portable stroboscope RT STROBE pocketLED T

Task: When manufacturing measuring devices for clinical diagnostics, an enzymatic amperometric bio-sensor is the heart of manufacturing. During the project, a process should be developed for the automated manufacture of these reusable sensors.

Application report - Quality assurance within the paper industry with portable stroboscope RT STROBE qbLED

Task: The surrounding conditions during paper production have very high requirements on material and machine. The challenge is to find a device which can be used in many different conditions in the paper industry.

Application report - Determining the pulsation rate of sprays with RT STROBE pocketLED

Task: Determining the pulsation rate of sprays when using an “effervescent atomizer” for the atomization of fluids for spray drying.

Application report - Turbine test rig with stationary stroboscope RT STROBE 5000 XENON

Task: To examine the whole operating environment of a Francis turbine, various operating curves are followed and the related measured values are recorded which supply the information for calculating the machines’ properties.

Application report - Maintenance of bone shavers with portable stroboscope RT STROBE pocketLED

Task: The rotational speed of the bone shaver is measured and adjusted accordingly using hall sensors. During various tests in the development phase, it is necessary to execute a reference measurement for the hall sensor measurement without any stress. In the future, the use of a stroboscope during manufacturing and in the later maintenance is planned.

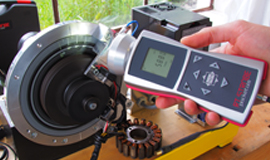

Application report - Setting up a prototype test rig for tacho generators with RT STROBE super qbLED

Task: The tacho generators should be monitored over a period of 2,000 hours in both directions checking rotational speed and the wear of the individual components.

Application report - Visualisation of components on vibration test rigs with RT STROBE qbLED

Task: Components or samples on a vibration test rig should be visualized through the use of the portable stroboscope in combination with the BNC adapter.

Application report - Representation of the cooling process with stat. stroboscope RT STROBE 5000 LED

Task: At an exhibit, the cooling process on an up-turning CNC milling machine should be visualized.

Application report - Validation and calibration of welding equipment with digital hand-tachometer rotaro Tw

Task: The speeds of welding wires for manual welding systems, robot welding plants and longer conveyor lines need to be measured (WPQR = Welding Procedure Qualification Records).

Application report - Quality control of printing machines with stationary stroboscope RT STROBE 10000 LED

Task: On an 8-colour flexographic printing press, there is a web inspection system whereby several individual frames are automatically sent to a monitor every second over the entire width of the material using a mobile camera.

Application report - Quality assurance with portable stroboscopes of the RT STROBE qbLED series

Task: Electrical components are checked on a vibrating table for resistance to vibrations. In this way weak points of the construction can be detected in advance.

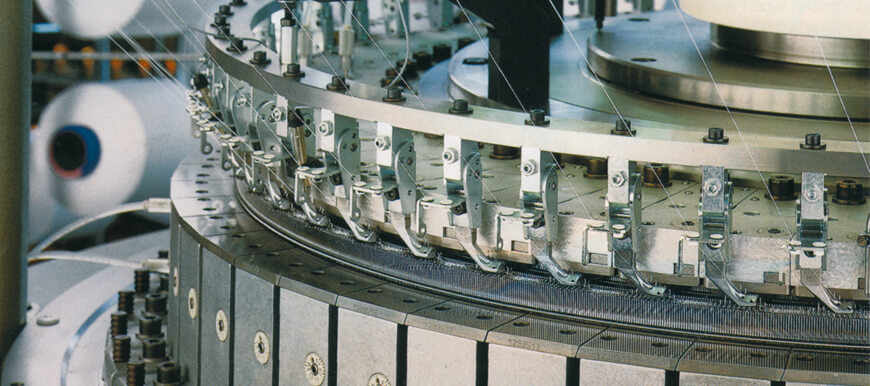

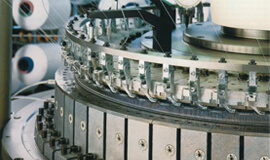

Application report - Inspection of a circular knitting machine with portable stroboscopes

Task: The guides, rollers and needles are to be checked during the inspection of a circular knitting machine in operation.

Application report - Service / Maintenance of pumps with digital hand-tachometer redpoint

Task: The speed of a pump driven by an electric motor has to be checked on a weekly basis in accordance with an internal quality guideline.

Application report - Service / Maintenance of electric motors with digital hand-tachometers redpoint / rotaro

Task: During the production of electric motors, the speed is to record at a certain current consumption during the final test.

Application report - Inspection of electric motors with portable stroboscopes

Task: An electric motor is to be checked regularly in accordance with an internal maintenance regulation. This inspection also includes the measurement of the speed and the inspection of the fan blades.

Application report - Maintenance of a weaving machine with digital hand-tachometer rotaro T

Task: The thread speeds of a weaving machine are to be checked with a handheld measuring instrument. No threads may be torn or errors to the woven product caused by the measurements.