Task:

Every type of turbine has its own special application: depending on the volume flow to be processed, the existing drop height and the rotational speed of the machine, the suitable geometry is determined. This is measured on site on a test rig to be able to ensure the best possible effectiveness for each unit, to know the operating behavior of the machine as well as possible and to defend and expand the technological advance permanently.

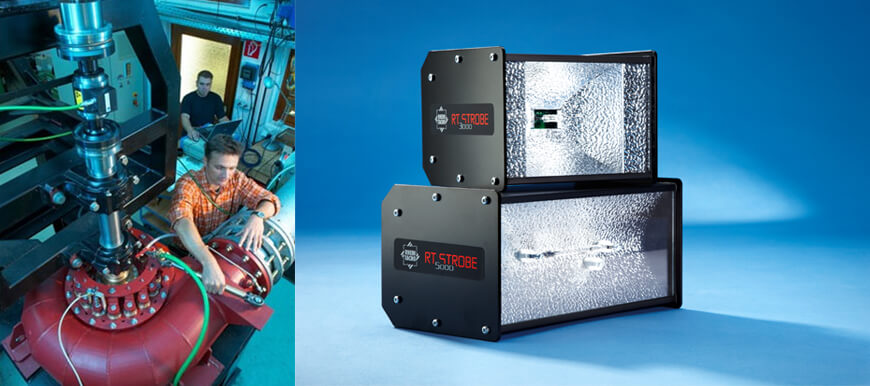

To examine the whole operating environment of a Francis turbine, various operating curves are followed and the related measured values are recorded which supply the information for calculating the machines’ properties. In addition, visual examination of cavity behavior and whirl phenomenon is carried out which take place through the transparent suctionpipe of the machine.

Solution:

The RT STROBE 5000 XENON (A6-5000) offers the perfect solution for this with its high intensity of light. After a test phase on site, we decided to additionally use the RT STROBE Control (A6-1000) as well as the Machine sensor (N0001.746) as a trigger solution. The RT STROBE Control unit, which enables a simple control of the stroboscope and the settings of all parameters offers the ideal complement. Hence, all necessary components are provided for the final solution, making the synchronization between drive and stroboscope possible.