Task:

Normally, a vehicle with a standstill manual transmission must stop for shifting. This not only costs a lot of time - but also a lot of energy.

When shifting gears while driving, however, the advantages are obvious: in addition to saving time, the kinetic energy of the machine that remains in motion is still used and fuel consumption is reduced.

Therefore, in the higher gears, a high starting torque is no longer required. Because of this, the transmission ratio in the higher gears could be increased. This reduces the required revolution of the hydrostats and the diesel engine. This in turn allows the diesel to operate in a more fuel-efficient range.

Solution:

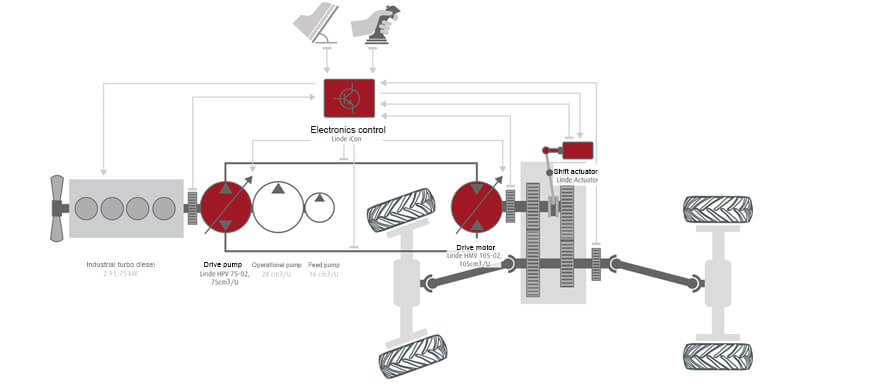

Work at low driving speeds, shift smoothly while driving and accelerate up to over 40 kilometres per hour - without any CVT or powershift transmission?

This is possible thanks to electro-hydraulic synchronisation with Shift in Motion from Linde Hydraulics. Extremely fast and precisely adjustable hydrostats, a shift actuator and an intelligent control unit take care of the adjustment. This eliminates the need for complex mechanical synchronization components.

Shift in Motion is particularly suitable for vehicles with a drive power of 40 to 300 kilowatts, which frequently change between transport and operation and drive at a maximum speed of more than 25 kilometers per hour.

The sensor solution - FC rotational speed sensors from RHEINTACHO

The sensor electronics of the FC series is designed as a 2-Channel Differential-Hall sensor. Due to a special brass alloy, the sensor is especially designed for high temperature resistance (up to 160 °C) and higher pressure loads. Thanks to an intelligently designed sealing system, the brass sensor achieves protection class IP69K.

The sensors of the FC series have an extremely arrow toleranced phase shift of 20°. This is why the sensor provides an extremely precise signal when detecting the direction of rotation and enables very sensitive control.

The FC series is available in several designs:

- with different plugs

- with different insertion depths (30 mm, 35 mm, 45 mm)