Task:

A sensor is required to measure the speed of hydrostatic drives and transfer it securely to the control system under extreme environmental conditions.

Applications:

- Road construction machinery such as excavators, crawlers and rollers;

- Snow plows and municipal vehicles;

- Agricultural machines;

- Truck cranes and special vehicles.

Operating conditions:

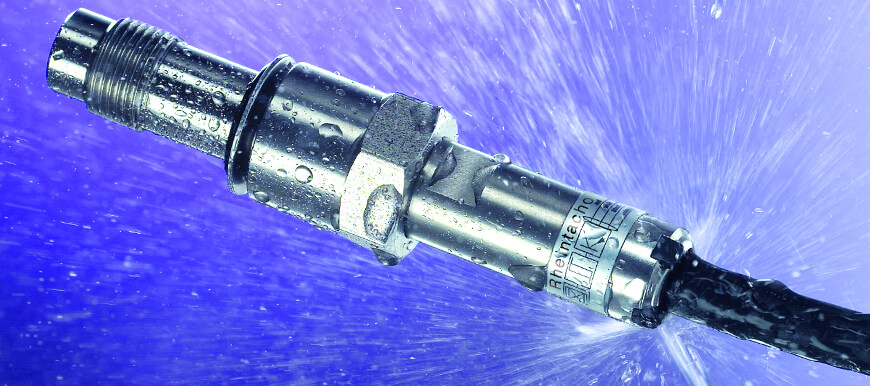

The sensor is attached directly to the hydro motor. It must be resistant against high-pressure cleaners (80 bar / 80 °C), contact with hydraulic oils, salt water and diesel and high pressures (approx. 360 bar) and temperatures.

Solution:

Special stainless steel differential hall-effect sensors are used. They are of a high protection class and can be used within a range of –40 °C to +125°C. Applications of up to 360 bar are possible due to a simple, but effective seal technology. Low speeds are also detected (from 0.5 Hz).

Scanning distances of up to 2.5 mm are possible. Various variants of the M12 high-pressure sensor series are available. They are available with different cable lengths or with an integrated connector.